industry insights

Featured Articles

Why Do You Need Updated As-Builts on Your Next Project?

Ground Penetrating Radar: Should You Rent, Buy, Or Hire?

Why Substance Abuse is the Biggest Safety Issue in Construction

When we talk about construction safety, it’s easy to stick to what we know: proper PPE, harnesses and lifelines, trench shields, etc. Every safety director on a job site reminds construction crews daily about the potential hazards they face.

However, when it comes to talking about arguably the biggest safety problem on any project – one that takes the lives of 131 out of every 100,000 construction workers – there is often silence.

Because it’s hard to talk about substance abuse and addiction in the middle of a hard-driving construction site. When you’re on the job, the schedule is everything; the pressure to just “suck it up” and perform is intense. And in an industry where taking your eye off the ball for a second can cause a fatal accident, working while high puts everyone at risk.

Josh Vitale, a construction supervisor with Hoffman Construction Company, one of the founders of the GUTS project/Tough Enough To Talk, and Vice Chair of Construction Suicide Prevention Week shared some sobering statistics:

Construction Workers:

- Are seven times more likely to die of an opioid overdose than workers in other industries

- Have the highest proportion of heroin-related overdose deaths

- Represent about 25% of fatal opioid overdoses among all workers

The National Survey on Drug Use, administered by the Substance Abuse and Mental Health Administration, reports that construction workers deal with substance and alcohol disorders at nearly double the rate of any other industry. The national average for an “alcohol use disorder” is 7.5%; that rate skyrockets to 12% among construction workers, and they are 150% more likely to be diagnosed with a substance use disorder than other full-time workers.

Vitale shared harrowing stories of drug and alcohol-related accidents, injuries, and overdose deaths he’s dealt with personally on sites he has supervised.

“Construction requires workers to sacrifice their bodies for decades. It’s no wonder they’re self-medicating for chronic pain. It’s not uncommon to see multiple overdoses per project. It has become commonplace, and that fact is tragic.”

Construction Dive reported that at the micro level, the overdose rates were highest among roofers (177.4 per 100,000), drywall installers & tapers (175.1 per 100,000), and painters (162.1 per 100,000). The stressors that accompany construction work, seasonal employment, downtime between jobs, and the physical strain of performing the work are all contributing factors that lead to substance use and abuse.

And as part of a 2022 round table on mental health in construction, Cindy DePrater said, “Research shows when employers initiate and support treatment for mental health disorders and substance misuse, it is more effective in the long term than at the urging of family or friends. When we take care of ourselves, we feel safer. When we take care of ourselves, it also becomes easier to support others.”

Part of the issue with overdose and suicide deaths in construction is gender specific. Construction is still a heavily male industry, and the suicide rate for workers is four times higher than the general population, according to the U.S. Department of Labor. That may also play a part in why it is so difficult for construction workers to seek out help.

As DePrater pointed out, and Vitale agrees, one solution is to bring the help directly to those who need it. That is how the Get Us There Safely (GUTS) Project was born.

with the GUTS initiative.

GUTS’ goal is to provide a decompression space on site for construction workers. They’ve placed 10 trailers on jobsites throughout the U.S., and one in Israel, that contain private rooms for telehealth & teletherapy appointments, a lounge area to allow for a quiet moment, and some entertainment like foosball tables and dart boards. Vitale characterizes a GUTS trailer as having all the characteristics of a bar, without any of the damaging substances.

GUTS and Tough Enough To Talk aim to provide anyone in need a space to de-stress, breathe, and maybe to talk before making an unfortunate choice. And as anyone on a job site knows, getting a construction worker to open up about anything is a very tall order. That’s why Construction Safety Week (CSW) began to feature mental health and substance abuse materials to their safety talks in 2020 and have continued to center mental health and physical health concerns in this year’s theme – Value Every Voice.

Just like knowing the best practices to avoid slips, trips, and falls, your mental health and wellbeing are crucial to your ability to perform at your peak and stay safe. So let’s value every voice by listening, even when it’s tough to talk about it.

Construction Safety Week is May 10-14, 2024. GPRS offers complimentary CSW talks on job sites throughout the nation. Schedule yours today.

Mapping America's Infrastructure Renaissance: The Role of Accurate Infrastructure Mapping in Ongoing Revitalization Efforts

America’s infrastructure is receiving some much-needed TLC, in large part due to the influx of funding courtesy of the Bipartisan Infrastructure Act.

As construction cranes dot the skyline and bulldozers break ground on transformative projects, the importance of accurate infrastructure mapping cannot be overstated. In a world where time, budget, and safety are paramount concerns, precise mapping powered by Geographic Information Systems (GIS) technology, utility locating, ground-penetrating radar (GPR), and electromagnetic locating emerges as the linchpin for keeping these endeavors on track.

The Bipartisan Infrastructure Act: A Catalyst for Change

With over $1 trillion allocated to a diverse array of projects spanning transportation, water systems, broadband expansion, and energy infrastructure, this legislation represents a seismic shift in how America approaches infrastructure investment. From repairing crumbling roads and bridges to expanding high-speed internet access in underserved communities, the Bipartisan Infrastructure Act heralds a new era of progress and opportunity for communities across the United States.

The Critical Role of Accurate Infrastructure Mapping

At the heart of any successful infrastructure project lies accurate mapping—a comprehensive understanding of the existing physical and spatial landscape upon which new developments will be built. Infrastructure mapping, facilitated by advanced GIS technology, enables project planners and engineers to visualize, analyze, and manage complex data sets related to land use, topography, utilities, and infrastructure assets. By harnessing the power of GIS, stakeholders can make informed decisions, optimize project designs, and mitigate risks before construction begins.

Utility Locating: Unveiling the Hidden Infrastructure

One of the primary challenges in infrastructure development is navigating the labyrinth of underground utilities that crisscross beneath our feet. From water and sewer lines to electrical cables and telecommunications infrastructure, accurately locating buried utilities is essential to avoid costly and potentially dangerous conflicts during construction. GPR and electromagnetic locating techniques offer invaluable tools for non-destructive utility mapping, enabling project teams to identify and map underground assets with precision. By integrating utility locating into the mapping process, project planners can proactively address potential conflicts, minimize disruptions, and ensure the safety of workers and the public.

Enhancing Safety Through Comprehensive Mapping

Safety is paramount on any construction site, and accurate infrastructure mapping plays a pivotal role in safeguarding workers and the surrounding community. By mapping potential hazards such as underground utilities, unstable terrain, and environmental risks, project teams can develop comprehensive safety plans and protocols to mitigate risks and prevent accidents. GIS technology enables real-time monitoring and analysis of safety-related data, empowering project managers to identify emerging risks and implement proactive measures to ensure a safe working environment.

Keeping Projects on Time and on Budget

In the fast-paced world of construction, time is money, and delays can have significant financial implications. Accurate infrastructure mapping enables project teams to optimize project schedules, streamline workflows, and identify potential bottlenecks before they occur. By integrating GIS data with project management tools, stakeholders can track progress, manage resources, and anticipate challenges, keeping projects on track and within budget.

GPRS: Mapping the Path to a Brighter Future

As America embarks on a historic infrastructure renaissance, accurate mapping emerges as the cornerstone of success. From the halls of Congress to construction sites across the country, the Bipartisan Infrastructure Act is paving the way for transformative change.

By harnessing the power of GIS technology, utility locating, and advanced mapping techniques, GPRS allows stakeholders in the construction industry to navigate the complexities of infrastructure development with confidence, ensuring that projects are completed safely, efficiently, and with lasting impact.

From skyscrapers to sewer lines, GPRS Intelligently Visualizes The Built World® to keep your projects on time, on budget, and safe.

What can we help you visualize? Click below to schedule a service or request a quote today!

Frequently Asked Questions

What are the Benefits of Underground Utility Mapping?

Having an updated and accurate map of your subsurface infrastructure reduces accidents, budget overruns, change orders, and project downtime caused by dangerous and costly subsurface damage.

How does SiteMap® assist with Utility Mapping?

SiteMap®, powered by GPRS, is the industry-leading infrastructure management program. It is a single source of truth, housing the 99.8%+ accurate utility locating, concrete scanning, video pipe inspection, leak detection, and 3D laser scanning data our Project Managers collect on your job site. And the best part is you get a complimentary SiteMap® Personal Subscription when GPRS performs a utility locate for you.

Click here to learn more.

Does SiteMap® Work with my Existing GIS Platform?

SiteMap® allows for exporting of data to SHP, GeoJSON, GeoPackage, and DXF directly from any user’s account that either owns or has a job shared to their account. All these file formats can be imported and utilized by other GIS packages if manually imported by the user. More information can be found at SiteMap.com.

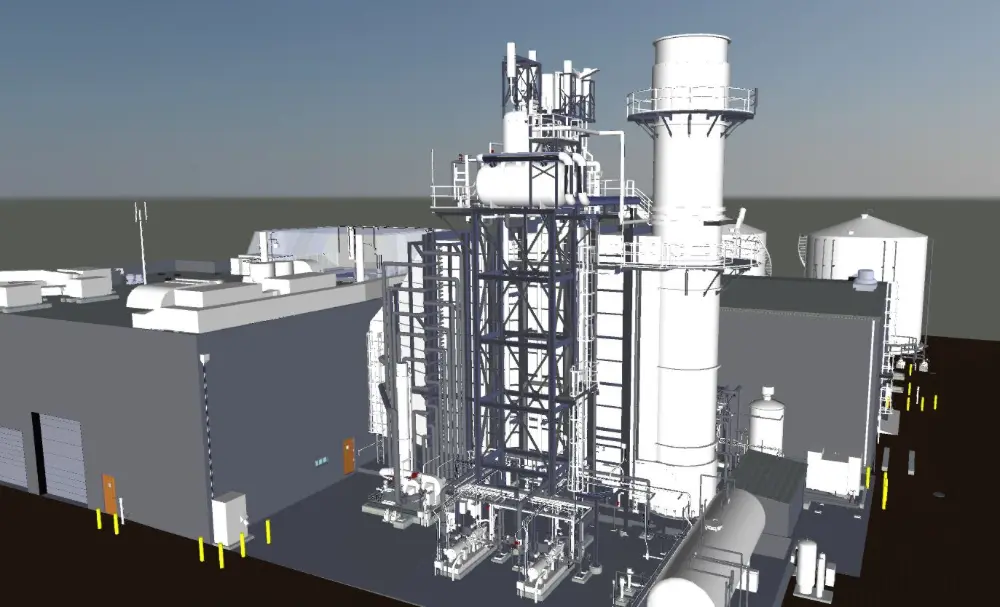

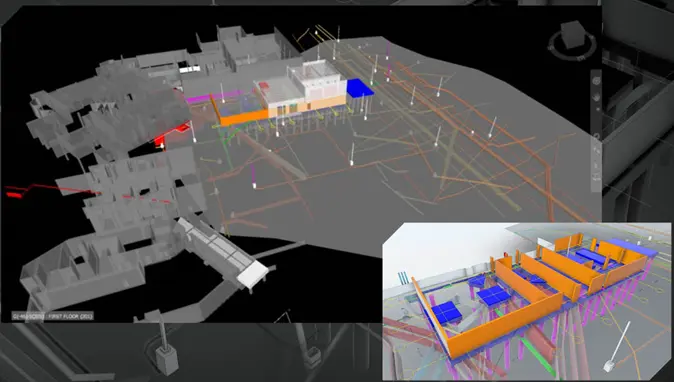

How Building Information Modeling (BIM) Improves Construction Safety

Safety is one of the primary concerns of every construction professional. It shapes every facet of project planning, execution, and management.

As technology continues to revolutionize the industry, one innovation has emerged as a game-changer in the quest for safer worksites: Building Information Modeling (BIM). This sophisticated digital toolset not only revolutionizes project visualization and coordination but also serves as a powerful ally in enhancing safety protocols and mitigating risks across construction projects of all scales.

Understanding Building Information Modeling (BIM)

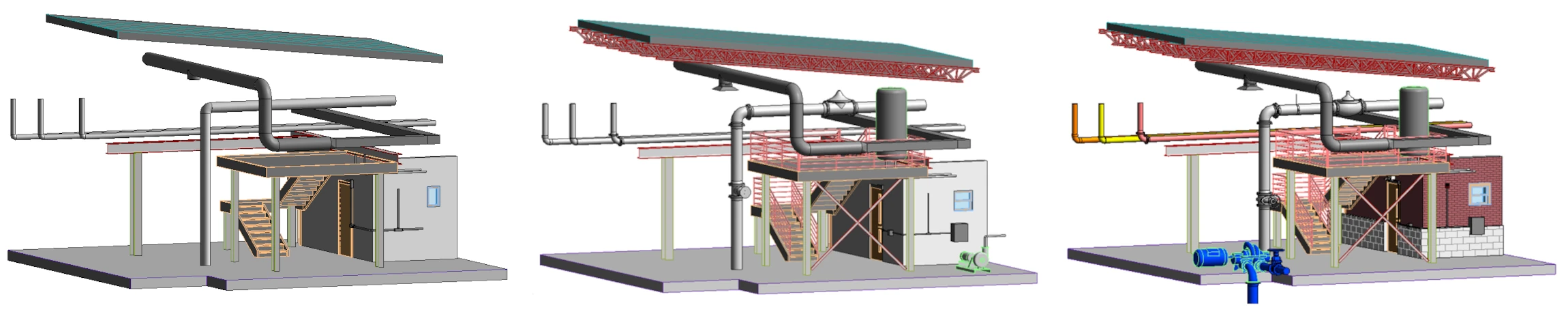

At its core, BIM is a digital representation of the physical and functional characteristics of a building or infrastructure project. Unlike traditional two-dimensional drawings or blueprints, BIM encompasses a comprehensive database of information, including geometric data, spatial relationships, materials specifications, and performance attributes. This multidimensional approach enables stakeholders to visualize, simulate, and analyze various aspects of a project before construction begins, fostering greater collaboration, efficiency, and insight throughout the project lifecycle.

The Role of BIM in Safety Enhancement

While BIM offers a myriad of benefits across the construction spectrum, its impact on safety is particularly profound. By leveraging advanced visualization, simulation, and analysis capabilities, BIM empowers project teams to identify and address safety hazards proactively, resulting in safer worksites and reduced incidents of accidents or injuries.

Enhanced Planning and Design

BIM enables designers and engineers to create detailed digital prototypes of structures, allowing for early identification and mitigation of safety risks during the planning and design phases. By simulating various construction scenarios and analyzing potential hazards, such as clashes between building components or accessibility challenges, designers can make informed decisions to optimize safety without compromising project objectives.

Clash Detection and Coordination

One of the hallmark features of BIM is its ability to facilitate clash detection and coordination among various building systems and components. By integrating architectural, structural, mechanical, electrical, and plumbing (MEP) models into a single, unified platform, BIM allows project teams to identify and resolve clashes or conflicts before they manifest in the field. This preemptive approach not only streamlines construction workflows but also minimizes the likelihood of on-site accidents resulting from clashes or interferences.

Virtual Construction and Simulation

BIM enables virtual construction and simulation, providing stakeholders with a realistic, immersive preview of the project before construction commences. Through virtual walkthroughs, simulations, and 4D scheduling, project teams can visualize the construction process in detail, identifying potential safety hazards, logistical challenges, and workflow optimizations. This proactive approach empowers teams to implement safety measures and protocols early in the project lifecycle, reducing the risk of accidents or delays during actual construction.

Site Safety Planning and Analysis

BIM supports site safety planning and analysis by providing tools for hazard identification, risk assessment, and safety simulation. Project teams can utilize BIM to conduct virtual safety audits, assess site logistics, and evaluate the effectiveness of safety measures such as fall protection systems, signage, and emergency egress routes. By simulating various scenarios and analyzing their potential impact on safety, teams can develop comprehensive safety plans that prioritize the well-being of workers and mitigate project risks.

Collaborative Decision-Making

BIM fosters collaborative decision-making among project stakeholders, including architects, engineers, contractors, and subcontractors. By sharing a common data environment and real-time project information, teams can communicate effectively, coordinate activities, and address safety concerns in a timely manner. This collaborative approach promotes transparency, accountability, and shared responsibility for safety across the project team, ultimately leading to safer worksites and better project outcomes.

The Role of BIM Services in Safety Enhancement

To harness the full potential of BIM in enhancing safety, many construction firms rely on specialized BIM services and BIM modeling services. These professional providers offer expertise in BIM implementation, training, support, and project management, helping organizations leverage BIM to its fullest extent for safety improvement. From initial project planning to construction execution and facility management, BIM services play a crucial role in integrating safety considerations into every phase of the project lifecycle.

In an industry where safety is non-negotiable, BIM has emerged as a transformative force, empowering project teams to proactively identify, assess, and mitigate safety risks across all stages of construction. By leveraging advanced visualization, simulation, and analysis capabilities, BIM enables enhanced planning, coordination, and decision-making, leading to safer worksites, reduced accidents, and improved project outcomes.

As the construction industry continues to embrace digital innovation, the role of BIM in safety enhancement is poised to become even more indispensable, driving a culture of safety excellence and innovation for years to come.

GPRS Provides Industry-Leading 3D Laser Scanning, BIM Services

As the foremost provider of 3D laser scanning and BIM modeling services, GPRS is reshaping the landscape of mechanical, electrical, and plumbing (MEP) design processes. Our cutting-edge laser scanning technology captures precise measurements of existing structures, while our BIM modeling seamlessly integrates this data to ensure accurate visualization and coordination of MEP elements. This meticulous approach not only optimizes spatial layouts but also enhances efficiency and drastically reduces errors and rework, culminating in unparalleled results for our clients' projects.

GPRS leads the charge in supporting MEP installation projects nationwide, boasting extensive expertise in 3D laser scanning and utility locating.

Our SIM-certified Project Managers leverage state-of-the-art Leica laser scanners, ground-penetrating radar, and electromagnetic locators to meticulously gather as-built site conditions. And our in-house Mapping and Modeling Team compiles this data into bespoke utility maps, 2D CAD drawings, and immersive 3D BIM models.

This comprehensive suite of deliverables is seamlessly integrated into SiteMap®, our proprietary cloud-based infrastructure mapping software solution. SiteMap® offers a user-friendly interface that provides access to georeferenced utility data, CAD files, and BIM models, all within a single platform, ensuring streamlined collaboration and informed decision-making throughout the project lifecycle.

What can GPRS help you visualize? Click below to schedule a service or request a quote today.

Frequently Asked Questions

How long does 3D laser scanning take?

An individual scan usually takes between 1-2 minutes. Your GPRS Project Manager will set up the scanner in multiple positions around your building or site. Most building scanning projects can be laser scanned in as little as a couple of hours, but larger sites may take a few days. Entire facilities or campuses can take several weeks to capture.

How much does 3D laser scanning cost?

The cost of 3D laser scanning a building or site depends on the size and complexity of what is being scanned. 3D building information modeling (BIM) costs are based on the size of the area being modeled, level of detail (LoD), and features needing to be included. 3D laser scanning can bring tremendous cost savings to a project. Quality data can lead to a faster design process and fewer change orders, ultimately saving time and money.

Is BIM only suitable for large projects?

No. Building information modeling (BIM) provides comprehensive site information that brings value to projects of all shapes and sizes. BIM management will expedite planning, improve workflows, and increase collaboration – which means that implementing BIM laser scanning will lead to cost and time savings, regardless of the project scale and complexity.

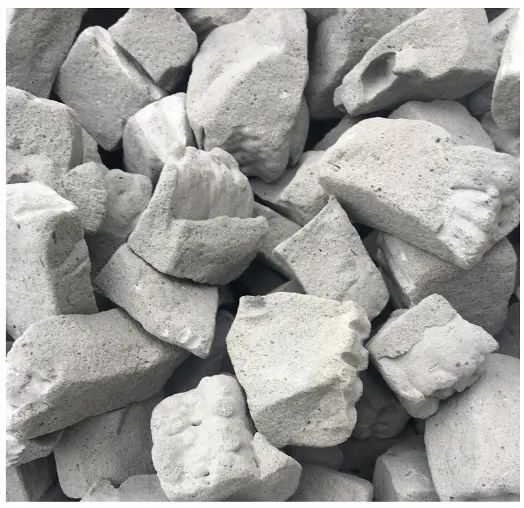

The Vital Role of Grounding Grids in Power Infrastructure

In the intricate web of power infrastructure, grounding grids stand as silent guardians, ensuring the safety and integrity of electrical systems. While they may not garner the spotlight like towering transmission lines or imposing substations, grounding grids play a pivotal role in protecting personnel, equipment, and the surrounding environment from the perils of electrical faults and surges.

Understanding Grounding Grids

At the heart of every electrical substation lies a grounding grid, a network of conductive materials strategically buried beneath the earth's surface. This grid serves as a low-impedance path for fault currents, diverting them away from sensitive equipment and structures. By providing a stable reference point for electrical potential, grounding grids mitigate the risk of equipment damage, electrical fires, and personnel injury in the event of a fault or lightning strike.

Ensuring Continuity and Integrity

Maintaining the continuity and integrity of the grounding grid is paramount for its effectiveness. Any discontinuities or degradation in the grid's conductive elements can compromise its ability to safely dissipate fault currents. Periodic testing and maintenance are essential to identify potential issues such as corrosion, loose connections, or inadequate soil resistivity, ensuring that the grounding system remains robust and reliable.

The Importance of Locating and Mapping Grounding Grids

Given the critical role of grounding grids in safeguarding power infrastructure, it's imperative to accurately locate and map these systems before undertaking any excavation or trenching activities in their vicinity. Failure to do so can have dire consequences, ranging from equipment damage to severe injury or even loss of life.

Excavation work near grounding grids poses a significant risk of inadvertent contact with energized conductors. Without precise knowledge of the grid's location, workers may unknowingly breach its protective perimeter, exposing themselves to the danger of electric shock or electrocution.

Grounding grids are designed to divert fault currents away from critical equipment and structures. Any disruption to the grid's integrity due to excavation-related damage can compromise its ability to fulfill this crucial function, potentially leading to costly equipment failures or service disruptions.

Excavation activities conducted without proper consideration for grounding grids can result in environmental damage, such as soil contamination or disruption of natural habitats. By accurately locating and mapping these systems beforehand, environmental impacts can be minimized, ensuring responsible stewardship of the surrounding ecosystem.

Mitigating Risks Through Proactive Measures

To mitigate the risks associated with excavating near grounding grids, it's essential to adopt a proactive approach that prioritizes safety and adherence to best practices:

Utility Locate Services: Engage the services of professional utility locating companies equipped with specialized tools and expertise to accurately identify the location of grounding grids and other buried utilities. Ground penetrating radar (GPR) and electromagnetic (EM) locating can be invaluable in this regard, providing precise mapping of subsurface infrastructure.

Communication and Coordination: Establish clear communication channels between project stakeholders, including utility owners, excavators, and construction crews. Develop a comprehensive excavation plan that incorporates the identified locations of grounding grids and outlines measures to avoid interference or damage during the excavation process.

Safety Training and Awareness: Provide comprehensive safety training to all personnel involved in excavation activities, emphasizing the importance of identifying and respecting the presence of grounding grids and other electrical infrastructure. Promote a culture of safety awareness and accountability to minimize the risk of accidents or incidents.

GPRS Helps Safeguard Power Infrastructure

Grounding grids are an indispensable element of power infrastructure, providing a vital layer of protection against electrical hazards. By accurately locating and mapping these systems before excavating or trenching near them, we can mitigate risks, protect personnel and equipment, and ensure the continued reliability and resilience of our electrical networks.

GPRS offers 99.8%+ accurate utility locating services designed to mitigate the risk of subsurface damage by providing you with the information you need to break ground safely. Using ground penetrating radar scanners and electromagnetic locating, our SIM-certified Project Managers create comprehensive infrastructure maps to keep you on time, on budget, and safe.

What can we help you visualize? Click below to schedule a service or request a quote today!

Frequently Asked Questions

Why are grounding grids important?

Grounding grids play a crucial role in ensuring the safety and integrity of electrical systems. By providing a stable reference point for electrical potential, they mitigate the risk of equipment damage, electrical fires, and personnel injury in the event of a fault or lightning strike.

How does a grounding grid work?

During normal operation, a grounding grid remains dormant, with little to no current flowing through it. However, in the event of a fault or lightning strike, the grid provides a low-resistance path for fault currents to dissipate harmlessly into the earth, diverting them away from sensitive equipment and structures.

What are the risks associated with excavating near grounding grids?

Excavation activities conducted near grounding grids pose significant risks, including the potential for inadvertent contact with energized conductors, damage to the grid's integrity, and environmental impact. Without proper precautions and awareness, excavation-related incidents can result in equipment failures, service disruptions, or even injury or loss of life.

Uncovering the Veiled: The Intricacies of Locating Buried Utilities

Beneath our feet lies a labyrinth of essential infrastructure, a network of buried utilities that powers our modern world.

From electrical cables to water pipes, these lifelines remain unseen, hidden from view, yet vital for our daily lives. However, when it comes to construction or excavation projects, ignorance of these underground assets can lead to costly damages, service disruptions, or even dangerous accidents.

The solution? A meticulous process of utility locating, employing advanced technologies and professional expertise to unveil the secrets hidden beneath the earth's surface.

Federal law requires that before you dig you must call your state’s 811 one-call service to provide you with the approximate location of all buried public utilities on your job site.

But it’s important to remember that 811 contractors do not locate private utilities, which make up 60% of all buried infrastructure in the U.S. This means that to ensure you won’t hit anything when you break ground, you need to hire a private utility locating company in addition to contacting 811.

Understanding the Need for Utility Locating

Before delving into the intricacies of utility locating, it's crucial to grasp why it's indispensable.

Picture a construction crew breaking ground for a new building or a homeowner digging to plant trees in their backyard. Without prior knowledge of buried utilities, they run the risk of inadvertently severing power lines, puncturing water mains, or damaging telecommunication cables. Beyond the inconvenience and expense, such mishaps can pose serious safety hazards and lead to service outages.

The Role of Professional Utility Locating Services

Enter the professionals: utility locating specialists equipped with the tools and expertise to mitigate these risks. A professional utility locating company offers a comprehensive array of services tailored to identify and map the underground infrastructure accurately. These services are not limited to public utilities but also extend to private facilities, such as underground storage tanks, septic systems, and irrigation lines.

Tools of the Trade: Ground Penetrating Radar and Electromagnetic Locating

At the heart of utility locating are two primary technologies: Ground penetrating radar (GPR) and electromagnetic (EM) locating. GPR works by emitting high-frequency radio waves into the ground and analyzing the reflected signals to detect subsurface anomalies. This non-destructive method is particularly effective for locating non-metallic utilities like plastic pipes and concrete structures.

A ground penetrating radar scanner provides real-time data, allowing technicians to visualize the underground environment accurately.

On the other hand, Electromagnetic locating relies on electromagnetic fields to identify buried metallic objects. By transmitting signals through a transmitter coil and detecting them with a receiver coil, technicians can pinpoint the location and depth of metallic utilities such as power lines and metallic pipes. While electromagnetic locating is proficient in detecting metallic objects, it may encounter challenges with non-conductive materials.

Integration of GPS for Precision Mapping

In conjunction with GPR and electromagnetic locating, Global Positioning System (GPS) technology plays a pivotal role in utility locating. GPS enables technicians to geo-reference the detected utilities accurately, creating detailed maps of underground assets. These maps serve as invaluable resources for construction planning, excavation projects, and infrastructure maintenance, enhancing efficiency and minimizing risks.

The Utility Locate Process: Methodical and Precise

The utility locate process follows a systematic approach, combining advanced technologies with meticulous fieldwork. It typically begins with thorough research, including reviewing existing utility records, as-built drawings, and historical documentation. This preliminary phase provides valuable insights into the location and type of buried utilities present in the area.

With a comprehensive understanding of the site's underground landscape, technicians deploy a combination of GPR and electromagnetic locating equipment to conduct on-site surveys. They traverse the area methodically, scanning the ground surface and marking the detected utilities with paint or flags. Throughout this process, GPS technology ensures the accurate recording of each utility's location and attributes.

Challenges and Limitations

While utility locating technologies have advanced significantly in recent years, challenges and limitations persist. Factors such as soil composition, depth of burial, and interference from nearby structures can impact the accuracy of detection. Additionally, non-metallic utilities pose a unique challenge, as they may not produce strong electromagnetic signals and can be more challenging to detect with GPR alone. Consequently, a multi-faceted approach that combines various technologies and field expertise is often necessary to overcome these obstacles.

Through the integration of advanced technologies such as GPR, EM locating, and GPS, coupled with the expertise of our SIM-certified Project Managers, GPRS Intelligently Visualizes The Built World® to keep you on time, on budget, and safe.

What can we help you visualize? Click below to schedule a service or request a quote today!

Frequently Asked Questions

Does GPRS offer same-day private utility locating?

Yes, our professional Project Managers can respond rapidly to emergency same-day private utility locating service calls on your job site.

Will I need to mark out the utilities GPRS locates?

No, GPRS will locate and mark all utilities for you. We have a variety of tools and markers we can use to highlight the locations of utilities, underground storage tanks and whatever else may be hiding.

Can GPR be used to verify known measurements?

We can use GPR to cross-check the measured depth and location of a located utility with existing as-built plans to verify the accuracy of plans.

GPRS Conducts Utility Locating Services on Private Property in Maine

GPRS recently provided utility locating services to ensure safe trenching and excavation at a private residence in Maine.

GPRS helps commercial construction, AEC, and facility management customers Intelligently Visualize The Built World® to mitigate subsurface damage and create existing condition documentation on commercial projects.

However, the general contractor for this project had worked with GPRS on several large-scale projects across the United States and contacted us to locate and map buried utilities on the quarter-acre private property after discovering that existing as-built documentation was out of date and likely inaccurate.

While federal law requires that you contact your state’s 811 one-call service prior to excavating to obtain the estimated location of all public utilities on your job site, it’s important to remember that 811 contractors do not locate private utilities – which make up roughly 60% of all subsurface infrastructure in the U.S.

To ensure that you are safe to dig, it’s vital to hire a professional private utility locating company like GPRS in addition to calling 811.

In Maine, Senior Project Manager Peter Kessinger utilized ground penetrating radar (GPR) and electromagnetic (EM) locating to locate and map all utilities on the property.

GPR scanners emit radio waves into the ground or a concrete slab, and those waves interact with any buried objects hidden within. The scanner detects these interactions and displays them in a readout as a series of hyperbolas that vary in size and shape depending on the type of material located. GPRS Project Managers are specially trained to interpret these readouts to tell you the precise location of the buried objects and provide their depth within the ground or concrete.

EM locators detect the electromagnetic signals radiating from metallic pipes and cables. These signals can emanate from current flow in a live electrical cable, or a conductive pipe acting as an antenna and re-radiating signals from stray electrical fields and communications transmissions. Your Project Manager can also create a signal by applying current to a known pipe, allowing them to map that utility’s path through your property.

GPRS Project Managers typically use both GPR scanners and EM locators when mapping underground utilities. The technologies compensate for each other’s limitations and create a redundant confirmation when designating subsurface elements – a key component of Subsurface Investigation Methodology (SIM), the industry-leading training program that we use to educate our field team members.

Kessinger located and annotated the depth of multiple previously unknown buried utilities, and he also identified the location and depth of an existing septic leach field on the property.

Also known as a septic tank drain field or a leach drain, this component of a septic system acts as a disposal filter for organic material and consists of an underground system of perforated pipes adjacent to the septic tank. After contaminants and liquid waste have been broken down by bacteria in the tank, the material then flows into the leach field through underground pipes. As liquid travels through the leach field pipes, it will seep into the ground below and be naturally filtered by the soil.

Had the contractor struck a component of the leach field during excavation, they could have caused costly damage and contaminated the property’s soil with untreated wastewater. Fortunately, the accurate utility maps created using Kessinger’s field-verified data prevented this from happening.

All utilities on the property were marked with paint and flags on the ground so that the contractor had a visual guide to reference while excavating. Additionally, our PMs use a global positioning system (GPS) to collect data points of findings that are used to generate a plan, KMZ file, satellite overlay, or CAD file to permanently preserve results for future use.

All this data is at your fingertips 24/7 courtesy of SiteMap® (patent pending), GPRS’ cloud-based infrastructure mapping software solution that provides accurate existing condition documentation to protect your assets & people.

You receive a complimentary SiteMap® Personal subscription whenever you hire GPRS to conduct a utility locate, allowing you to securely review that data whenever and wherever you need it.

From skyscrapers to sewer lines, GPRS Intelligently Visualizes The Built World® to keep your projects on time, on budget, and safe.

What can we help you visualize? Click below to schedule a service or request a quote today!

GPRS’ SiteMap® team members are currently scheduling live, personal SiteMap® demos. Click below to schedule your demo and see how SiteMap® can help you plan, design, manage, dig, and build better today!

Frequently Asked Questions

Can GPRS find PVC piping and other non-conductive utilities?

GPRS scanning is exceptionally effective at locating all types of subsurface materials. There are times when PVC pipes do not provide an adequate signal to ground penetrating radar equipment and can’t be properly located by traditional methods. However, GPRS Project Managers are expertly trained at multiple methods of utility locating and can easily find PVC.

Can GPR be used to verify known measurements?

We can use ground penetrating radar (GPR) to cross-check the measured depth and location of a buried utility with existing as-built plans to verify the accuracy of plans.

Is GPRS able to distinguish between each type of underground utility that’s located?

In most situations, we can identify the utility in question without any problems, although it is not always possible to determine what type of utility is present. When this happens, we attempt to trace the utility to a valve, meter, control box, or other signifying markers to determine the type of utility buried.

Department of Energy Announces Rule Designed to Expedite Transmission Permitting

In what’s being touted as a part of the federal government’s continued commitment to bolster the U.S. power grid, the Biden-Harris Administration has announced a final transmission permitting reform rule and a new commitment for up to $331 million aimed at adding more than 2,000 megawatts (MW) of additional grid capacity throughout the Western United States.

The administration, through the Department of Energy (DOE) issued a final rule to establish the Coordinated Interagency Transmission Authorizations and Permits (CITAP) Program, which, according to an article on the DOE’s website, “aims to significantly improve Federal environmental reviews and permitting processes for qualifying transmission projects.”

“Under the CITAP Program, DOE will coordinate a Federal integrated interagency process to consolidate Federal environmental reviews and authorizations within a standard two-year schedule while ensuring meaningful engagement with Tribes, local communities, and other stakeholders,” the article continued.

The new rule expedites the siting, permitting, and construction of electric transmission infrastructure in the United States.

Resources provided by the CITAP Program include:

Improved Permitting Review with Two-Year Timelines: DOE will serve as the lead coordinator for environmental review and permitting activities between all participating federal agencies and project developers. DOE will lead an interagency pre-application process designed to ensure that developer submissions for federal authorizations are ready for review on binding two-year timelines, without compromising critical National Environmental Policy Act (NEPA) requirements.

Sustained Integrity in Environmental Review Process: DOE will work with the relevant agencies to prepare a single NEPA environmental review document to support each relevant federal agency’s permit decision making, with the goal of reducing duplication of work. State siting authorities may participate in the CITAP Program alongside federal agencies and take advantage of the resources DOE is offering through the program.

Transparent Transmission Permitting: The CITAP Program will require a comprehensive public participation plan that helps project developers identify community impacts from proposed lines at the outset of the project and encourages early engagement by potential applicants with communities and tribes. The CITAP Program will allow potential applicants and agencies to coordinate via an online portal, which will allow project developers to directly upload relevant information and necessary documentation and will offer a one-stop-shop for their federal permitting communications. Through this online portal, participating federal agencies can also view and provide input during the initial document collection process and during federal environmental reviews.

“The Permitting Council is excited to have CITAP as a partner as we work together to bring clarity, transparency, and efficiency to the federal permitting process for crucial transmission projects,” said Permitting Council Executive Director, Eric Beightel. “The ambitious clean energy goals of the Biden-Harris administration cannot be achieved without the transmission infrastructure needed to deliver renewable energy to consumers. This rule is a significant step forward in bringing coordination and accountability into the permitting review of these vital projects, and a perfect complement to our FAST-41 permitting assistant program, enabling us to deliver clean and affordable energy to homes across the nation.”

The newly announced $331-million funding commitment will add grid capacity equivalent to powering 2.5 million homes and create more than 300 new, high quality and union construction jobs, DOE said. The funding comes courtesy of the Bipartisan Infrastructure Law and will support a new transmission line from Idaho to Nevada that will be built with union labor.

“…We are acting with the urgency the American people deserve to realize a historic rework of the permitting process that slashes times for new transmission lines, puts more Americans to work and meets the energy needs of today and the future,” said U.S. Secretary of Energy, Jennifer M. Granholm.

“In order to reach our clean energy and climate goals, we’ve got to build out transmission as fast as possible to get clean power from where it’s produced to where it’s needed,” added John Podesta, Senior Advisor to the President for International Climate Policy. “As today’s announcements demonstrate, the Biden-Harris administration is committed to using every tool at our disposal to accelerate progress on transmission permitting and financing and build a clean energy future.”

A Grid on the Brink

Federal, state, and even local government agencies are racing to solve the country’s current energy problems and prepare for those on the horizon.

The American Society of Civil Engineers (ASCE) gave the United States’ energy infrastructure a C- in its most recent Infrastructure Report Card.

“…Distribution infrastructure struggles with reliability, with 92% of all outages occurring along these segments,” the ASCE wrote. “In the coming years, additional transmission and distribution infrastructure, smart planning, and improved reliability are needed to accommodate the changing energy landscape, as delivery becomes distributed, and renewables grow.”

The U.S., like the rest of the world, needs to generate more power, and it needs to do it more efficiently.

In the International Energy Agency’s recently released 2024 Electricity Report, which analyzes and forecasts the world’s electricity needs through 2026, the organization said that power generation is currently the largest source of carbon dioxide (CO2) emissions in the world, but it is also the sector leading the transition to net zero emissions through the rapid expansion of renewable energy sources such as solar and wind power.

“Ensuring consumers have secure and affordable access to electricity while also reducing global carbon dioxide (CO2) emissions is one of the core challenges of the energy transition,” the IEA wrote.

Per the IEA’s report, global electricity demand rose moderately in 2023 but is set to grow faster through 2026 as electricity consumption from data centers, artificial intelligence (AI), and the cryptocurrency sector is projected to double by then.

“After globally consuming an estimated 460 terawatt-hours (TWh) in 2022, data centres’ total electricity consumption could reach more than 1,000 TWh in 2026,” the IEA added. “This demand is roughly equivalent to the electricity consumption of Japan. Updated regulations and technological improvements, including on efficiency, will be crucial to moderate the surge in energy consumption from data centres.”

GPRS Services Support Grid Expansion & Maintenance Projects

As the country continues looking for new ways to optimize and expand our power infrastructure, proper planning will be the first step in ensuring these projects can be completed on time, on budget, and – most important – safe.

GPRS offers a suite of subsurface damage prevention, existing condition documentation, and construction & facilities project management products and services to ensure the success of your next project.

Through concrete scanning, utility locating, video pipe inspection and leak detection, we mitigate the risks of subsurface damage – both financial and to your team’s health & safety.

As you start to build, our 3D laser scanning, and photogrammetry capabilities give you the accurate as-built drawings, and building information modeling (BIM) you need to plan with precision. And all the field-verified data collected by our SIM and NASSCO-certified Project Managers, and modeled by our in-house Mapping & Modeling Team, is available to you 24/7, from any computer, tablet, or smartphone courtesy of SiteMap® (patent pending), GPRS’ cloud-based infrastructure mapping software solution.

We’re here to help you Intelligently Visualize The Built World®. Click below to schedule a service or request a quote today!

Frequently Asked Questions

What are the components of the U.S. power grid?

The U.S. power grid is a complex network of electricity production, transmission, and distribution systems that spans the entire country. It consists of three major interconnections: the Eastern Interconnection, the Western Interconnection, and the Texas (ERCOT) Interconnection. These systems work together to deliver electricity from producers to consumers across states and regions.

How is the power grid managed?

The U.S. power grid is managed by various organizations, including regional transmission organizations (RTOs) and independent system operators (ISOs). These entities coordinate, control, and monitor the grid's operation to ensure a stable and continuous supply of electricity. The Federal Energy Regulatory Commission (FERC) oversees the rules and regulations that these organizations must follow.

What are the main sources of power in the U.S. power grid?

The U.S. power grid utilizes a diverse mix of energy sources to generate electricity. These include fossil fuels such as coal, natural gas, and oil; nuclear power; and renewable sources such as wind, solar, hydroelectric, and geothermal energy. The mix can vary greatly depending on the region and its available resources.

How does the power grid handle peak demand?

To handle peak demand periods, grid operators use a combination of demand-response programs, where consumers are incentivized to reduce their usage during peak times, and peaking power plants that can be quickly ramped up to provide additional power. Advanced technologies such as grid energy storage and smart grid capabilities also play crucial roles in managing load and enhancing the grid's responsiveness.

What are smart grids?

Smart grids are an evolution of the traditional power grid, incorporating advanced technologies and communication systems to enhance the efficiency, reliability, and sustainability of electricity services. They include features like automated control systems, real-time energy management, and integrated renewable energy sources. Smart grids can predict and respond to changes in electricity demand and supply more dynamically and efficiently.

What challenges does the U.S. power grid face?

The U.S. power grid faces several challenges, including aging infrastructure, cyber threats, and the need for modernization to integrate more renewable energy sources. Additionally, extreme weather events driven by climate change pose significant risks to the grid's stability and reliability.

How is the power grid being modernized?

Modernization efforts for the U.S. power grid include upgrading old infrastructure, incorporating more renewable energy sources, enhancing grid security against physical and cyber threats, and implementing smart grid technologies. These initiatives aim to improve the grid's resilience, reduce carbon emissions, and accommodate future energy needs more effectively.

What Causes Leaning Towers?

You’ve heard of the Leaning Tower of Pisa – but what about the Leaning Tower of South Dakota?

In late 2023, a construction site in Rapid City, South Dakota, had to be evacuated when an elevator shaft for the 10-story, mixed-use structure began to tilt. According to local news outlet KELO, surrounding buildings and a section of a nearby street also had to be evacuated until repairs could begin.

Luke Jessen, Vice President of Development for Lloyd Construction, which is overseeing the project, said in a statement to Construction Dive that a product failed at the corner of one of the elevator shafts, causing the tower to shift one inch at its base.

“This is an isolated product and sequencing issue, which will be safely rectified by an erection subcontractor in the days to come by deconstructing the shaft.” Jessen’s statement said.

The incident in Rapid City is just the latest example of a leaning structure making the news.

The most famous is the aforementioned Leaning Tower of Pisa, the 60-meter medieval tower in Italy which stands about 17 feet off the vertical. That tower, however, is just one of several leaning structures in Pisa alone.

There are thousands of unintentionally tilted towers scattered throughout the world – and they’re not all historic structures. San Francisco’s Millennium Tower luxury condo required a $100-million foundation retrofit because it had been sinking since it opened to residents in 2009 and was tilting an estimated 14 inches by 2019.

The situation became more serious when the curtain wall – an exterior element of a building designed to protect it from the elements – had pulled away from the tower and created a gap that could have served as a funnel for flames in the event of a fire.

Determining the causes, consequences, and solutions for leaning buildings falls under a branch of civil engineering known as geotechnical engineering – also known as geotechnics – which focuses on the engineering behavior of earth materials.

In an article published in February 2020 on CNN Style, leading civil engineer John Burland – who designed the solutions that stabilized both the Tower of Pisa and Britain’s Big Ben – explained that the Earth itself is the most frequent culprit behind modern leaning towers.

“We are very sophisticated in our analysis now, but we still have to understand how mother nature works,” Burland said. “Mother nature lays down ground in all sorts of variable ways and unless you actually spend the money and the time investigating the ground properly – and employ people with good knowledge and experience – then you can run into big problems… If it’s mother nature then it’s human error because they haven’t investigated it properly.”

In addition to faulty construction materials – as was the case with the elevator shaft in South Dakota – soft or weak spots in the ground, unexpected geological faults, and incomplete ground investigations can also cause structures to lean.

Burland added that most of the leaning buildings he’s worked with are “not unsafe,” but that “selling space in a building that has been known to be leaning is very difficult because often the leaning is caused by some defect in construction or design.”

“The trouble with a tall building is that you can see it leaning, which people don’t like,” he added. “It might be safe, but the owners of the building are not going to be at all happy.”

GPRS Helps Ensure Project Success

Whether you’re building a tower or a rehabbing a bridge, GPRS offers a suite of subsurface damage prevention, existing condition documentation, and construction & facility project management services designed to keep your projects on time, on budget, and safe.

Our concrete scanning, utility locating, video pipe inspection, and leak detection services help maintain the integrity of existing infrastructure and protect it from damage during groundbreaking activities. Using a blend of technologies including ground penetrating radar (GPR) scanners, electromagnetic (EM) locating, CCTV camera-equipped sewer inspection rovers, acoustic leak detection and leak detection correlators, our SIM and NASSCO-certified Project Managers (PMs) provide you accurate, highly detailed information about where your infrastructure is located and its condition.

Accurate measurements help you avoid expensive mistakes, rewords, and change orders. GPRS 3D Laser Scanning services provide 2-4mm accuracy by capturing 2 million data points per second, for efficient planning, design, and construction. And our in-house Mapping & Modeling Team can export your GPR utility locates & concrete scans, 3D laser & photogrammetry data, and video pipe inspection reports to create accurate existing condition as-builts – above and below ground – to give you the accurate information you need in a format you can easily work with and share to keep your project on track.

All this field-verified data is available to you 24/7, from any computer, tablet, or smartphone, courtesy of SiteMap® (patent pending), GPRS’ cloud-based infrastructure mapping software solution which allows you and your team to plan, design, manage, dig, and ultimately build better.

From skyscrapers to sewer lines, GPRS is ready to help you Intelligently Visualize The Built World®.

What can we help you visualize? Click below to schedule a service or request a quote today!

*Please note that GPRS does not investigate, analyze, or interpret soil composition, soil conditions, or geological or geophysical information. GPRS reports retrieved data and does not provide geophysical, geological, engineering, or land surveying services. Please contact a professional in those fields if such services are needed.

Frequently Asked Questions

Does GPRS Perform S.U.E. Work?

Subsurface Utility Engineering (SUE) reduces the risk and improves the accuracy of subsurface utility readings. It is broken down into four levels of quality, governed by ASCE Standard 38-02. GPRS provides private utility locating services but does not currently provide a fully comprehensive in-house SUE service. GPRS does not provide engineering services. If you need professional engineering services, please contact a professional engineer.

How Quickly Can GPRS Respond to an Emergency Need?

In most circumstances, we can have a Project Manager on your site within 24 hours of contact. Click here to schedule a service or request a quote today.

What is the Farthest GPRS Will Travel to Reach a Site?

Our nationwide team of SIM-certified Project Managers is strategically placed in every major market across the country, so you always have precision concrete scanning & imaging, utility locating, 3D laser scanning, video pipe inspection, leak detection, and mapping & modeling services near you.

CoStar Group Buys Matterport 3D Reality Capture and Digital Twin AI Technology

On April 22, 2024, CoStar Group, Inc. announced its plans to purchase construction tech company Matterport for an estimated $1.6 billion in “enterprise value,” according to its press release.

As one of the self-described “first adopters” of Matterport’s technology, CoStar references the wide swath of data the 3D capture technology company has amassed; “Over 12 million spaces captured in over 177 countries, and representing more than 38 billion square feet of digital property.”

It appears that another substantial reason for CoStar’s acquisition is the artificial intelligence software, Cortex, that Matterport is touting as an AI engine for digital twin generation, virtual tours, and measurements. Matterport recently added a suite of “Property Intelligence” AI features and plug-ins to aid AEC contractors working in large spaces.

However, there seems to be some question as to the accuracy rate of the AI-generated images, specifically those 2D images taken with cameras other than Matterport. An article from Geo Week News quotes Matterport business development manager Tomer Poran as saying that the AI accuracy rate for those kinds of images have up to an 8% error rate.

Matterport maintains that its accuracy rate when using their own technology is still 1% or less.

GPRS utilizes Matterport technology as part of our reality capture services, and our WalkThru 3D, FLRPLN, and ProCap products. It has tremendous value in its ability to capture our 99.8% accurate field markings to allow our Mapping & Modeling Team to create integrated digital twins that incorporate above and below-ground infrastructure to provide a 360-view of any site or facility.

These integrated 3D BIM models and 2D CAD drawings can even incorporate proposed design and renovation plans to avoid or eliminate clashes, utility strikes, or strikes to concrete reinforcements before they happen.

All GPRS drawings, maps, and models are delivered via our proprietary infrastructure data, facility and project management software, SiteMap® (patent pending). Every GPRS customer receives a complimentary SiteMap® Personal subscription as part of our service.

For a greater level of detail (LoD) for your existing conditions, GPRS provides complete 3D laser scanning (LiDAR) services with 2-4mm accuracy.

More on Matterport’s Sale

CoStar Group, the multinational corporation dedicated to “digitizing the world’s real state,” was founded in 1987 and has been on a buying spree the last few years, having previously acquired OnTheMarket, Houses.com, Homes.com, Off Campus Partners, Move, Fairmas, and RealBase, among others.

The specifics of the Matterport acquisition include a $5.50 per share purchase price. Matterport shareholders will receive a $2.75 cash pay-out and $2.75 in CoStar shares for every Matterport stock currently held.

The $1.6 billion valuation may seem generous. However, the Costar purchase price reflects a steep downward valuation from the $9.8 billion market cap (a 480% annual valuation and 88.5 times its 2021 revenue) it boasted after its initial public offering (IPO) in 2022.

Some construction and infrastructure watchers cite Matterport’s decision to shift into a recurring revenue/subscription model as the cause of its slide. But its vast trove of aggregated data, and expanding pipeline to grow it, may be exactly what enticed CoStar to purchase them – to bolster their own data network while also wiping out potential competition.

Or, perhaps it is as Andy Florance, CoStar Group CEO put it in the press release announcing the acquisition, “People now select their next home, apartment, office, store, hotel or warehouse on their mobile devices, often without ever visiting the property. There is no better way to remotely experience space than via Matterport.”

Frequently Asked Questions

How does Matterport work?

Matterport cameras provide 3D photogrammetry, which means they allow you to capture a 360-degree, 3D view of your space via individual images that can be carefully stitched together, AKA rectified, to provide accurate spatial and geographical documentation. Read more about 3D photogrammetry, here.

How do I get a 3D walkthrough or BIM model of my site or facility?

GPRS offers full site visualization via our 3D photogrammetry and 3D laser scanning services. A Project Manager can usually scan a site or facility in a matter of hours or days, although large sites may require weeks to fully capture.

If we have provided utility locating or concrete scanning at the site, 3D photogrammetry can capture those field markings and allow our in-house Mapping & Modeling Team to assemble an accurate Walkthru 3D virtual tour. If 3D laser scanning is also employed on site, GPRS can create a fully integrated above and below-ground BIM model that is accurate to 6mm for existing condition documentation, planning, and design purposes. Learn more about 3D scanning here.

From Data to Action: SiteMap®’s Impact on Infrastructure Mapping for Utilities

In an era dominated by digital necessities and advancements, our reliance on technology grows ever stronger.

This digital transformation permeates every aspect of our lives, extending even into the very soil beneath our feet—mapping and shaping the world around us in ways previously unimaginable. In this increasingly digital landscape, efficient management of infrastructure assets emerges as a linchpin for ensuring the reliability, safety, and sustainability of urban environments.

Utility managers face a unique set of challenges in managing their intricate networks of underground infrastructure, including water and sewer lines, electrical cables, and telecommunications networks. To confront these challenges head-on, utilities are embracing advanced solutions like SiteMap® (patent pending), powered by GPRS, to revolutionize the way they map, monitor, and manage their infrastructure assets. Let's delve into how SiteMap® transforms data into actionable insights.

The Evolution of Infrastructure Mapping

Traditionally, infrastructure mapping relied on manual surveys, paper records, and outdated mapping tools, leading to inaccuracies, inefficiencies, and limited visibility into underground assets. However, visionary pioneers like Roger Tomlinson, often hailed as the father of Geographic Information Systems (GIS), paved the way for a deeper understanding of the subsurface. Tomlinson's innovative spirit was born out of necessity during his work as a photo interpreter for Spartan Air Services in Canada in the early 1960s.

Tasked with finding a new methodology to solve a complex problem—identifying the optimal location for a tree plantation in Kenya—Tomlinson turned to a revolutionary solution: the computer. By harnessing GIS technology, Tomlinson reduced a three-year, $8 million project to just several weeks and $2 million, catalyzing a seismic shift in infrastructure mapping from rudimentary ink pen drawings to the detailed, three-dimensional mapping we rely on today.

Empowering Utilities with SiteMap®

Today, utilities have access to powerful tools for digitizing and visualizing their infrastructure assets, with SiteMap® representing the pinnacle of this evolution. SiteMap® offers utilities a comprehensive solution for storing, visualizing, and analyzing infrastructure data, transforming how they manage their assets in the digital age.

Key Components of SiteMap®'s Impact:

1. Data Collection and Integration: SiteMap® streamlines data collection by integrating 99.8% accurate data from GPRS locate orders, providing utilities with a unified view of their infrastructure assets. The data is meticulously collected, visualized, aggregated, and tagged to facilitate navigation through the subsurface landscape.

2. High-Resolution Mapping: SiteMap® generates high-resolution, easy-to-understand maps of underground infrastructure, enabling utilities to visualize the precise location, depth, and condition of their assets. This level of detail is crucial for identifying conflicts, planning excavation activities, and minimizing the risk of damage to underground utilities.

3. Anywhere Monitoring: SiteMap® empowers managers to monitor infrastructure assets from any device, anywhere and anytime, providing real-time updates on assets and potential hazards.

4. Data Portability with External Systems: SiteMap® offers seamless data portability with external systems and tools, allowing utility managers to leverage existing investments and maximize the value of their infrastructure data.

The Safety of SiteMap®

SiteMap® is unique in its backing by the remarkable power and accuracy of GPRS. Safety and accident prevention are top priorities at Ground Penetrating Radar Systems, ingrained in the company's core values and culture. GPRS prioritizes continuous safety education for all employees, ensuring compliance with rigorous construction standards and industry-leading safety practices.

Connecting & Communicating

Effective communication is paramount, particularly in preventing utility strikes—a common and serious hazard in the industry. SiteMap® breaks down communication barriers by providing easy-to-understand maps and information accessible to all team members, regardless of their level of expertise. With features like the Digital Plan Room and Map Viewer, SiteMap® fosters collaboration, eliminates confusion, and creates a single source of truth for all stakeholders.

Navigating the Future of Infrastructure Mapping

As project managers grapple with challenges posed by aging infrastructure, climate change, and rapid urbanization, SiteMap® emerges as a beacon of innovation and safety. By streamlining data collection, providing high-resolution mapping, and fostering communication and collaboration, SiteMap® is revolutionizing the way utilities map, monitor, and manage their infrastructure assets. Much like Tomlinson's pioneering spirit, SiteMap® is solving common problems in smart, forward-thinking ways, guiding utilities toward a safer, more resilient future.

GPRS SiteMap® team members are currently scheduling live, personal SiteMap® demonstrations. Click below to schedule yours today!

Efficient Operations: SiteMap® and the Role of Infrastructure Asset Management in Modern Business

In today's fast-paced world, the relentless pace demands efficient operations for organizations striving to remain competitive and adaptable.

At the core of this efficiency lies the effective management of infrastructure assets, including vital utilities such as water, sewer, electricity, and telecommunications networks. SiteMap® (patent pending), powered by GPRS, emerges as a comprehensive solution to the pressing question of digital utility mapping. Let's delve into the significance of infrastructure asset management and how SiteMap® is revolutionizing the way businesses map, monitor, and manage their utility infrastructure.

The Significance of Infrastructure Asset Management

Infrastructure assets serve as the lifeblood of modern society, providing essential services that fuel business operations, support thriving communities, and drive economic growth. Effective management of these assets is paramount for ensuring reliability, sustainability, and resilience in the face of evolving challenges such as aging infrastructure, population growth, and climate change.

Meeting the Energy Challenges

The sprawling cities aboveground are mirrored by a complex network of utilities below, forming the arteries and veins that sustain life above. Subsurface assets constitute the source of over 80% of the energy in the U.S. today. This underscores the critical importance of proper management. The Subsurface Science, Technology and Engineering Research, and Development (SubTER) Crosscut, a collaboration across Department of Energy (DOE) offices, aims to address subsurface challenges and advance solutions, ensuring access to vital subsurface resources.

Infrastructure's Role in the Economy

Investment in infrastructure has historically laid the foundation for economic growth. Analysts emphasize the multiplier effect of infrastructure spending, with every public dollar invested yielding $1.50 in economic activity, according to a 2022 World Bank analysis. Neglecting infrastructure could have dire consequences, with estimates indicating a potential infrastructure investment gap of nearly $2.6 trillion by the end of the decade, resulting in substantial losses to GDP.

Transportation Troubles

The transportation sector faces significant challenges, with one in three bridges in need of repair or replacement. Furthermore, aviation infrastructure struggles with delays, costing the economy billions annually. The rail system, crucial for freight movement, faces challenges, with Amtrak grappling with a repair backlog exceeding $45 billion. These issues underscore the interconnectedness of subsurface infrastructure with aboveground resources and the importance of proper management.

Current Utility Infrastructure Stability

Utility infrastructure, including water and electrical grids, faces urgent needs for investment. The Environmental Protection Agency estimates a required investment of over $744 billion in drinking water and wastewater systems over the next decade. The Flint Water Crisis serves as a stark reminder of the consequences of neglecting subsurface utility management, highlighting the critical need for proactive measures.

The Role of SiteMap® in Infrastructure Asset Management

SiteMap® offers a comprehensive suite of digital utility mapping solutions designed to streamline infrastructure asset management. Leveraging advanced technologies, SiteMap® enables accurate mapping, monitoring, and management of utility infrastructure with precision and efficiency. By integrating 99.8% accurate data from GPRS, SiteMap® creates a centralized repository of infrastructure asset information, facilitating informed decision-making and proactive action to prevent downtime and service disruptions.

The Greater Importance

Effective utility infrastructure management is vital for ensuring the smooth functioning of modern societies. The urgent need for efficient management practices to maximize the lifespan and performance of existing infrastructure assets cannot be overstated. Utility failures can have significant economic consequences, with inadequate infrastructure costing families thousands annually and posing risks to public safety and health.

The Benefits for Business

SiteMap®'s remarkable 99.8% accuracy rating for utility and concrete infrastructure mapping provides unparalleled precision, enabling businesses to make informed decisions and minimize risks associated with underground infrastructure. By confidently planning construction projects, avoiding utility strikes, and ensuring compliance with regulatory requirements, businesses can achieve greater reliability, resilience, and success in their operations.

Efficient operations are essential for businesses seeking to thrive in today's competitive marketplace, with effective management of infrastructure assets being central to achieving this efficiency.

SiteMap® plays a crucial role in streamlining infrastructure asset management, providing visibility, high-resolution mapping, and advanced technologies to optimize utility infrastructure, reduce downtime, and enhance operational efficiencies. As we navigate the complexities of the modern infrastructure landscape, SiteMap® emerges as a beacon of innovation, guiding businesses toward success and growth in a rapidly evolving world.

GPRS’ SiteMap® team members are currently scheduling live, personal SiteMap® demos. Click below to schedule your demo today!

How Power Substation Operators Can Reduce Risk and Increase Efficiency with SiteMap®

Power substations are the veins that provide the lifeblood of America’s electrical grid.

That’s why protecting them at all costs whenever construction or maintenance is occurring near them is of the utmost importance.

National Grid states that “one of the main roles of substations is to convert electricity into different voltages.” This electricity is then distributed throughout the U.S. and provides the essential energy needed to thousands of homes, businesses, and buildings to keep us going along throughout our days without interruption. It’s extremely important to prevent underground electrical line damage when installing new fencing at a major substation, as was the case in Oregon, Ohio, for a well-known national security integration provider.

Electrical Substation Maintenance, Scope of Project

The contractor hired the SIM-certified team of GPRS Project Managers who have completed over 3,000 miles of Transmission ROW scanning & over 500 substation projects nationwide for major companies such as Duke Energy, American Electric Power, Ameren, FirstEnergy and Exelon, to ensure that the electrical substation construction they were performing would move forward without any hazardous utility strikes, causing potential loss of power, electrocution, or electrification of the grid around the station.

Our scope of work at the power transmission substation was to provide accurate utility location of all underground utility lines located within ten feet of both sides of the main fence that was scheduled to be replaced. This proved to be a large project for GPRS Project Manager Vijay Gentiles, who spent an entire week accurately mapping and locating telecommunication lines, electrical lines, water hydrants, an existing sanitary sewer line, as well as the entire grounding wire grid located within the fence’s domain.

Why It Matters

Power substations are high-risk areas to break ground due to essential utilities being located throughout the majority of the system. So, the best practice is hiring a nationwide subsurface damage prevention contractor such as GPRS to utilize the most cutting edge locating and mapping protocols. In this scenario and many others like it, the substation’s as-built drawings and existing condition records were out of date and incomplete, not providing the sufficient data needed to break ground with confidence on site. Crucial duct banks needed to be protected along with essential grounding grids during installation, so Gentiles sprung to action equipped with multiple forms of cutting-edge technology, including Ground Penetrating Radar (GPR), and an Electromagnetic (EM) locator to accurately map out the proposed scan boundary for all underground utilities.

What We Discovered

While on site, Gentiles had to be extremely cautious, wearing proper PPE including fire retardant clothing per OSHA standards in case of an arc flash. As he conducted his meticulous subsurface investigation, he was able to locate both electrical and telecommunication lines throughout the entirety of the substation’s fence project. He discovered a sanitary storm line in one location, but found that it would not impact the project due to its depth.

The depths of the located lines were between two to three feet underground, while the sewer line was conveniently at a depth of five to six feet, where new fence poles being installed would not reach. After accurately mapping and marking out the lines with paint or color-coded flags, as shown in the images below, Gentiles then collected all the data with a GNSS Geode used to accurately inspect, map, and collect data points of underground utility locations. The site data was then uploaded to the cloud, and within five minutes of being collected was available within our new GIS for electric & telecommunication utilities software, SiteMap®.

The data collected by Gentiles and uploaded to SiteMap® provided an accurate below-ground digital map of the entire scan location as shown in the image below, giving a breakdown of each utility line and approximate depth where applicable.

How SiteMap® Enhances Substation Construction Safety

Every GPRS customer gets a complimentary SiteMap® Personal subscription with any GPRS utility locate project performed on their job site. This means that our customer’s superintendent was able to easily reference this accurate as-built map throughout the remainder of the fence replacement project. This gave him control to easily break down the as-built map to ensure he saw only what was needed for each leg of the project. From individual telecommunication lines as displayed in figure 2. To the entire as-built map as shown in figure 1. SiteMap® gave our customer what they needed, when they needed it, with the ease-of-use and constructability to be tailored to their needs.

Paint and flags on the ground, provided immediate visual representation of where underground lines were located on site. While SiteMap® provided an easy-to-use, geolocated, and a shareable digital utility map of all the data collected in the field by Gentiles. This information was accessible for the project superintendent on any tablet, computer, or mobile device 24/7, so that our customer was able to move forward with this electrical substation construction fence project without the frightful experience of a damaged electrical line, or a damaged grounding rod. Not only did this provide peace of mind when digging, but it ensured the project was able to be completed on budget, on time, and safe.

With GPRS’ existing condition documentation, subsurface damage prevention, and facility and property management services, you can get a suite of accurate utility as-built data, 3D building information (BIM) models, and Walkthru 3D data of your electrical substation jobsite. This will not only enable you with the accurate data you need to dig with confidence, but will give you the ability to Intelligently Visualize The Built World® above and below-ground while on your job site, in your truck, or behind your desk.

The dangers of working in and around substations are many. Mitigate them with the accurate data collected by GPRS Project Managers and provided to you via SiteMap®.

Schedule your live, personal SiteMap® demo with one of our SiteMap® experts today to learn more.

Frequently Asked Questions:

What are other ways SiteMap® Can Provide Accurate Data for My Substation Construction or Maintenance Project?

SiteMap® can aid in substation facility and project management through the use of accurate existing condition documentation technology such as 3D laser scanning and 3D photogrammetry, to provide you with accurate 3D Point Clouds, 2D CAD drawings, 3D BIM models, 3D mesh models, and much more. We’ve performed work on over 500 substations across the country, accurately locating their subsurface infrastructure below ground, and digitally mapping their existing conditions on site above ground, compiling all that data within our GIS utility software to help you plan, design, manage, dig, and ultimately build better.

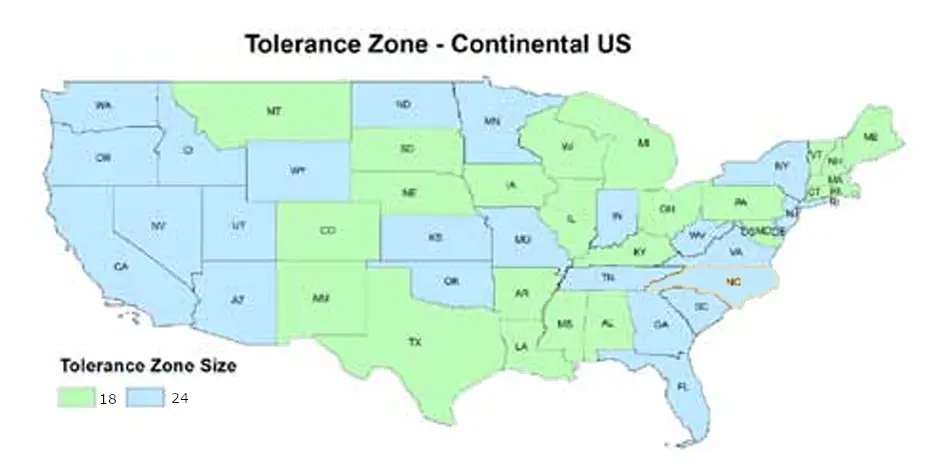

How do Excavation Tolerance Zones Protect Utilities?